- View Mobile Number

Heaters

Leading Manufacturers and Wholesaler of Air Heater, Cartridge Heater, Ceramic Band Heater, Flanged Tubular Heater and Mica Band Heater from Udaipur.

| Business Type | Manufacturer, Supplier |

| Power Source | Electricity |

| Application | Air Heating |

| Feature | Durable, Easy Installation, Eco Friendly, Fast Heating |

| Voltage | 5.110 V To 415 V |

| Sheath material | Stainless Steel, Inconel alloy, Titanium |

| Conductor | NiCr 80/20 |

| Watt Density | 3.up to 40 W/in2 |

| Insulation | 4.High-purity siliconized MGO |

| Resistance Tolerance | 6.±10% |

| H.V Tolerance | 7.0 mA@1500V |

| Max. Temp | 8.600 degree C |

AIR HEATER

FLOMAC offers an Industrial air heaters are designed to withstand the toughest conditions of the industrial air processing environment. They are designed to withstand dirt, vibration, and contamination. An industrial air heater utilizes an open coil of the heating element, which is inserted into the metal sheath, to directly heat the air. The design of the system and the direct heating process lead to the most efficient heating and the shortest heating times. Air heaters work by radiating heat into the passing air or fluid. There are various types of air heaters, including finned air heaters, tubular air heaters, and open coil air heaters. These industrial air heaters are available in standard and custom models.

Features

1. Sheathed heating elements help extend the life of your heating system and protect it from corrosion.

2. Integrated sensors enable the monitoring of over-temperature.

3. The edges are sealed to keep moisture out.

4. Terminal Enclosure is thermally insulated, which decreases heat loss

5. Fast heat up time

6. Easy installation

7. Increased efficiency

8. Lower Maintenance

Applications

1. Semiconductor industry for drying wafers and PC boards.

2. Preheating process gases / air

3. HVAC Systems

4. Industrial Ovens

5. Powder coating Plant

6. Air handling systems

7. Plastic Industry

8. Packaging Industry

| Business Type | Manufacturer, Supplier |

| Insulation | High Purity MGO Core & Powder |

| Length | 25mm To 2200 Mm |

| Diameter Range | 5 mm to 30 mm |

| Operating voltage Range | 12V to 480V |

| Conductor | Ni Cr 80/20 |

| Other Sheath | SS-304, SS-321, SS-310, incoloy 800 |

| Surface Load | 148 W/inch On Sheath – Depends On Diameter |

| Working temperature | up to 700°C on sheath |

| Resistance Tolerance | -5%, +3% |

| Diameter Tolerance | -0.02 to -0.05 |

| Length tolerance | ±1% or ±3mm |

| Leakage current | < 0.5mA |

| High Voltage Strength | 0ma@800v |

| Unheated Length | connection Side 10mm to 15mm & Bottom Side 10 Mm |

| integrated Thermocouple | Optional Available ‘j’ Type or ‘k’ Type Switchable Zones |

Cartridge Heater:

The High-Density Cartridge Heater is a key product offered by FLOMAC. Its exceptional heat transmission, consistent temperatures, resistance to oxidation and corrosion, and long lifespan—even at temperatures as high as 700◦ C—are all attributed to a careful production process using premium raw materials. Thousands of industrial manufacturers consistently select FLOMAC as their certified cartridge heater supplier and dependable thermal partner because it is the industry leader in swaged cartridge heating.

Standard Heaters Available with equal heat distribution but at the same time variable watt density can also produce upon request.

Features

1. Increase Heater Life

2. Resists moisture contamination

3. Resists abrasion and vibration

4. Protects against high temperatures without additional insulation

5. High emissivity sheath

6. Variable watt density Upon Request

Applications

1. Plastic Industries

2. Packaging industry

3. Pharmaceutical Industries

4. Food handling equipment

5. Zinc die-casting

6. General machine industries

7. Rubber Industries

8. Wood Working industries

| Business Type | Manufacturer, Supplier |

| Resistance Tolerance | -5%, +3% |

| Thickness | 12 Mm |

| Voltage | 110 V /230V/ 440 V |

| Length | 50 mm And Above |

| Brand Name | FLOMAC |

| Material | Steel |

| Sheath Material | Stainless Steel and anodize coated Galvanized sheet |

| Conductor | Ni-Cr 80/20 |

| Diameter | 50 mm and above |

| Insulation Thickness | 32mm/54mm/74mm |

| Watt Density | 25 W to 50 W/sq. Inch |

| Clamping | M6 Allen bolt with spring |

| Terminal | Junction Box, Junction Box with Breaded Wire, Post Terminal |

| Delivery Time | within 1 week |

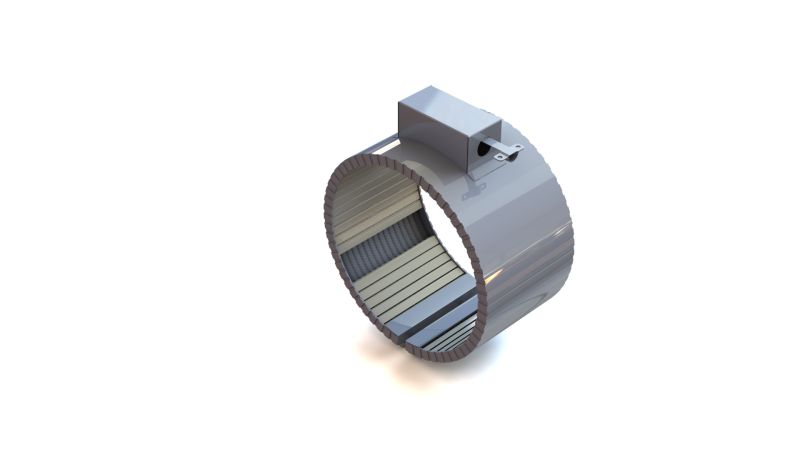

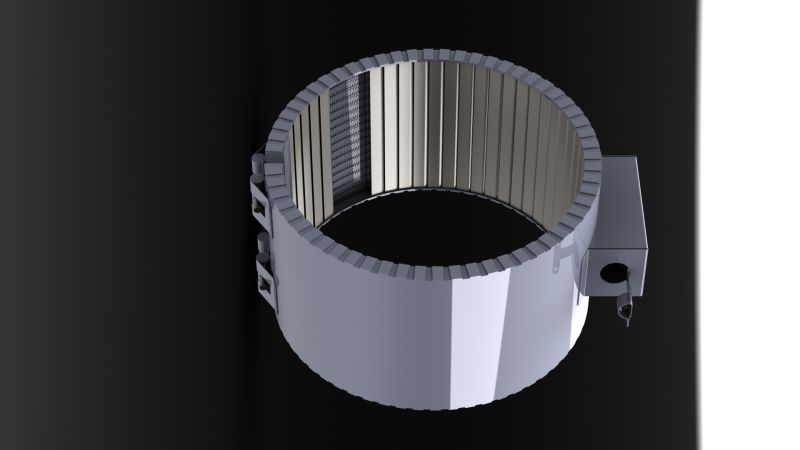

Ceramic Band Heater

FLOMAC offers Ceramic Band Heaters are engineered to suit industrial requirements for high-temperature, long-lasting heaters. These heaters are well-suited to fulfil the demands of today's modern resins, which require continual temperature increases during processing. Internal resistance coils are spirally coiled and laced through interlocking ceramic "Knuckle" in this ceramic band heater. The ceramic core or "mat" of the tiles is concealed beneath a stainless-steel sheet with serrated edges. The combination of the two makes this heating system both versatile and efficient. The ceramic band's heat comes from the inner coils, which conduct heat at high temperatures. They distribute heat uniformly across the tiles, which radiate energy into the barrel. We have a variety of ceramic band styles with different

Ceramic Band Heater Power Saver

Additionally, FLOMAC provides ceramic band heaters designed specifically for injection moulding machines and other applications requiring greater temperatures. Up to 30% less electricity can be used with these heaters. At a temperature of 250°C, the outer shell will be 70°C. the barrel's temperature measurement. The purpose of the element winding is to both convey energy through contact with the barrel and heat the ceramic blocks to the point where they radiate energy into it.

Perforated Ceramic Band Heater

We also provide perforated ceramic band heaters, which are commonly used in blow moulding machines, extrusion cooling, and PVC injection moulding. The perforated metal sheet allows the heater band to be 60% open, maximizing surface exposure for optimal cooling. A blower cover is placed over the heater band to mount the blower. Lower costs, ease of replacement, less maintenance, no leakage issues, and consistent temperature control are some of the benefits of air-cooled operations versus liquid-cooled ones.

Features

1. Superior heat transfer & uniformity

2. Easy Replacement & Low Maintenance

3. To Heat and Cool the Barrel

4. Improves Quality of finished products

5. Available with Various Diameter, Length, Voltage, Wattage and Configurations

6. Perforated heater will give faster cooling on barrel

7. Constant and long lasting efficiency

Applications

1. Blow Molding Machinery

2. Extrusion Machinery & Dies

3. Injection molding machines

4. Other Process Applications

5. Blow Film Co-ex Lines

6. Laboratory Equipment

| Business Type | Manufacturer, Supplier |

| Voltage | 110 V to 415 V |

| Sheath Material | Stainless Steel, Inconel Alloy, Titanium |

| Conductor | Ni-Cr 80/20 |

| Watt Density | up to 40 W/in2 |

| Insulation | 4.High-purity siliconized MGO |

| Resistance Tolerance | 6.±10% |

| Immersion Length | Customize |

| Length Tolerance | ±2% or ±5mm |

| High Voltage | 9.Tolerance : 0mA@1500V |

| Max. Temp | 750 degree C |

| Termination | Single & Double Ended |

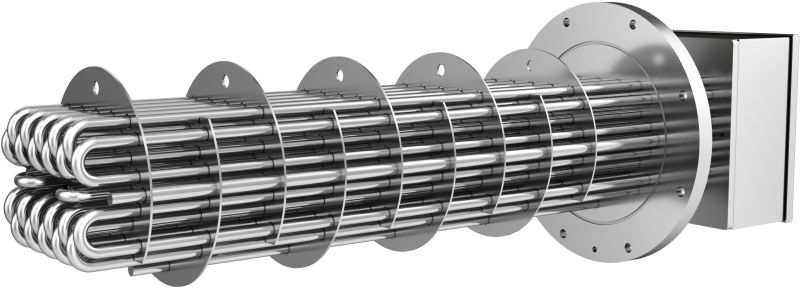

FLOMAC offers Tubular heaters are renowned for their adaptability, durability and reliability. They can be virtually factory-fitted to meet a wide range of industrial heating requirements. The fundamental principle of the design is to enclose a resistive wire or coil in a precisely centered metal sheath, surrounded by magnesium oxide, in order to facilitate the efficient transfer of heat from the coil to the heating medium. They can be designed in a wide range of electrical ratings, diameters, lengths, terminations, and sheath materials. Tubular heating elements are capable of conveying heat through all three of these modes: Conduction, Convection and Radiation. Tubular heating elements are available in single-ended and double-ended configurations. Tubular Heaters with a single-ended design have both terminals located at one end of the heater. The other end is sealed. Lead wires that are flexible and are crimped to the terminal pin are equipped with sleeves made of silicone-enriched fiberglass.

The double-ended is highly flexible in terms of bending, particularly when bending in the field. Both single-and double-ended structures have a lot of built-in features that help them last a long time.

Features

1. Designed to be sealed with either epoxy or silicone to prevent moisture ingress.

2. Compacted with MGO insulation, heat transfer from resistance wire to sheath material & media with faster, more efficient thermal expansion.

3. Integrated sensors enable the monitoring of over-temperature.

4. Fast Heat up time

5. Easy Installation

6. Increased Efficiency

7. Low Maintenance

Applications

1. Semiconductor industry for drying wafers and PC boards.

2. Preheating process gases / air

3. HVAC Systems

4. Industrial Ovens

5. Powder coating Plant

6. Air handling systems

7. Plastic Industry

8. Packaging Industry

| Business Type | Manufacturer, Supplier |

| Length | Min 20mm To 250 Mm |

| Voltage | 110V, 230V, 440 V |

| Thickness | 4mm |

| Clamping | M6 Allen Bolt With Spring |

| Sheath Material | Stainless Steel, Mild Steel, and Galvanized Iron |

| Diameter | Min 30 Mm to 600mm |

| Insulation thickness | 4mm + 6 mm |

| Watt Density | 10 W/ Sq. Inch |

| Resistance Tolerance | ±5% |

| Sheath Temp | 300°c Max |

| Terminal | Junction Box, Junction Box with Breaded Wire, Screw Terminal |

| Conductor | Ni Cr 80/20 |

MICA BAND HEATER

FLOMAC provides the Mica Band heaters as an economical and effective answer to the thermal requirements across different uses. These heaters can attain a surface temperature of up to 500°C. The thickness of each mica layer is chosen meticulously to maintain the mica's insulating characteristics while ensuring easy heat transfer from the heating element to the machine barrel. Mica band heaters feature a diverse selection of electrical connections and clamps, along with the capability to accommodate drilled holes and openings. They are versatile enough to be applied in various settings but are primarily utilized in the plastics sector.

Features

1. Very Effective Heat Transfer

2. Feasible for Small Length

3. Operating Temperature up to 280° Degree

4. Mica of superior quality with superior dielectric strength

5. Need Very Low Heating Time

Applications

1. Blow Molding Machinery

2. Extrusion Machinery

3. HDPE pipe jointing material

4. Square or rectangle shape die

5. Drum heating